The ZLJ combined conveyor tape sulfur sulfur connector can be used by a single machine sulfide and multi -combined use according to the length of the conveyor belt. The following is the main configuration of a single sulfur.

Host structure introduction:

1.Frame

2.Set bolt

3.Upper heating plate

4.Down heating plate

5.Water bag protection board

6.Rubber pressure bag

7.Water bag protection board

8.Insulation board

9.Fast cooling

10.Customizable socket

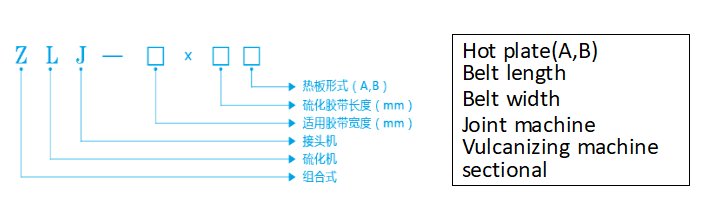

Model and specifications:

-In the applicable band width is divided into: 500,650,800,1000,1200,1400,1600,1800, 2000,2200 (mm);

-In the length of the tape joints is divided into: 250,300,350,400,500,600,700,800,830,1200 (mm);

-In thermal plate type divided into: type A-parallel square, 72 ° C; type B rectangular, 90 ° C;

-In the voltage level, it is divided into three voltage levels: 380V, 660V, 1140V;

-Accant configuration requirements can be divided into fast water cooling type and natural cooling type.

Main technical characteristics

-The electric heating type, pressurized method is hydraulic type;

-The applicable working power supply 1140V, 660V, 450V, 415V, 380V, 220V, 50Hz, the working voltage required for foreign customers can be customized;

-Cost the power supply voltage 1140V, 660V, 450V, 415V, 380V, 220V, 50Hz, the working voltage required for foreign customers can be customized;

-On block heating board heating power unit area ≥7000W/m;

-The automatic digital temperature control system, the vulcanization temperature is 0-199 ° C;

-The temperature time: (normal temperature to vulcanize temperature 145 ° C) Not greater than 25min;

-Table vulcanization pressure <2MPa;

-A fully automatic control over the protection of heating, heat preservation, and temperature super limits.

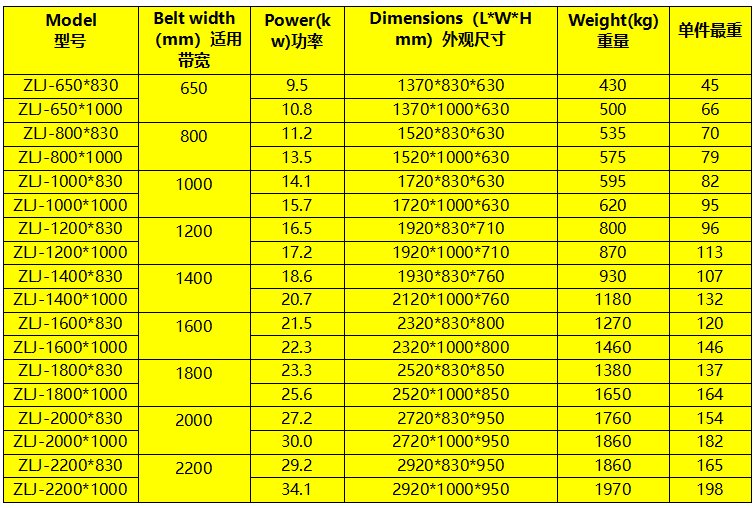

The main technical parameters

(This parameter table is filled in according to the conventional high -intensity aluminum alloy profile. Except for conventional sizes such as 830mm and 1000mm, it is customized by any non -standard size)

As a subsidiary of the company's export products, the sulfur packaging box uses the special structure of the non -fumigation packaging box and the special structure of the galvanized steel belt combined with the tongue -type lock. The packaging box, beautiful appearance, convenient loading and unloading, with a fumigation tray at the bottom, which meets the customs export standards.

Rubber Conveyor Belt Vulcanizers / Customizable

TECHNICAL DATA | |

Function | Conveyor Belt Hot Vulcanization Joint |

Application | Rubber Belt Splicing |

Material | Aluminium |

Pressure | As our experience, normal setting is 0.8Mpa; 1.2Mpa is for EP belts; 1.4Mpa is for steel cord belts. (Max. 1.8Mpa, Adjustable) |

Heating Way | Flexible Silicone Electric Heating Max. 200℃, Adjustable |

Vulcanizing Temperature | 145℃ |

Cooling Way | Built-in Water Circulation Cooling |

Cooling Time from 145℃ to 75℃ | ≤10minutes |

Belt Width | 650~3000mm |

Platen Length | 780~3250mm |

Bias Angle | 16°, 18°, 20°, 22°, 90° etc. |

Voltage

| 380V, 220V, 380V, 400V, 415V, 440V, 480V, 525V, 660V, etc. 50HZ/60HZ |

Total Weight | 208~3200KG |

Price | Negotiable |

PRODUCT DETAILS | |

Place of Origin | Qingdao City, China |

Brand Name | XINGHE KEER |

Certification | CE, ISO |

Packaging and Transport Way | Plywood Box by Sea |

Minimum Order Quantity | 1 Set |

Supply Capacity | 50 Sets Per Month |

Payment Terms | T/T |

Delivery Time | 3 ~4 Weeks |

Warranty | 12 Months |

Notes: —Before placing an order, please confirm Conveyor Belt Max. Width; Splice Length; Bias Angle; Vulcanization Pressure; Local Working Voltage. —We test running the vulcanizers before delivery to find out any potential fault. —We can record videos in English to provide sales and after-sales services. —We offer OEM service. Your logo can be printed on conveyor belt vulcanizers. | |

A=Length of Platen Along the Belt

B=Width of Platen Across the Belt on the Bias

C=Right Angle Dimension across the Belt, Plus Edge Overlap.

D=Bias Angle (0°/18°/20°/22° etc.)

E=Max Splice Length

If you have any questions or needs about the product, please fill in the following form and we will contact you as soon as possible.